The

Vacuum Truck

Innovators

Superior equipment you can trust

Australian Made Vacuum Tankers

Vacuum Trucks Built Just Right

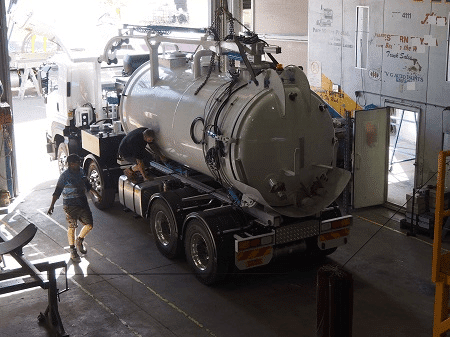

Vorstrom is an all-Australian company solely focused on the design, manufacture, sales and servicing of vacuum trucks & trailer units. We know that there’s no room for error when it comes to the liquid waste management and non-destructive digging industries.

To this end, we design, build and service our proven range of no-fail equipment right here in Australia. Find a wide range of vacuum truck models for sale in our gallery from 3000 to 24000 litre vacuum tanker trailers, hydro excavation, liquid, industrial and compact vacuum trucks.

Purpose-Built Vacuum tanks

Engineered For High Productivity

Vorstrom’s range of vac trucks have a good record and recognition as effective and efficient commercial vacuum loaders. These vacuum tankers are designed to retrieve, contain, and hold wet solids, dry bulk powders, liquid waste, and thick sludge from very difficult to reach areas.

View our full range of vacuum tanker units for sale, including the Rigid Series(R-Series), Tipping-Series(T-Series) and Tipping with full opening rear door Series (TRD Series).

Our Range

Vorstrom vac trucks & trailer units are designed to perform in any environment; under pressure, on your toughest jobs, when you need it most. View all vacuum trucks for sale.

Liquid Vacuum Units

Vorstrom liquid vacuum trucks are the perfect choice for any type of liquid waste including grease trap, septic and sewer waste and other types.

Industrial Vacuum Trucks

As the ultimate all-rounder, our industrial vacuum equipment is suited to any application whether it’s industrial cleaning, sludge pits and general liquid waste.

Hydro Excavation Trucks

Our hydro excavation equipment is built in-house to tackle the toughest of challenges and is flexibly designed to suit almost any style of truck and project.

Dangerous Goods Units

Vorstrom Dangerous Goods units are reliable, robust, dependable and suitable for the collection and transportation of hazardous liquid waste and chemicals.

Cab Chassis Combination

Customers

Most Popular Vacuum Trucks

Vacuum Tank Manufacturing Process

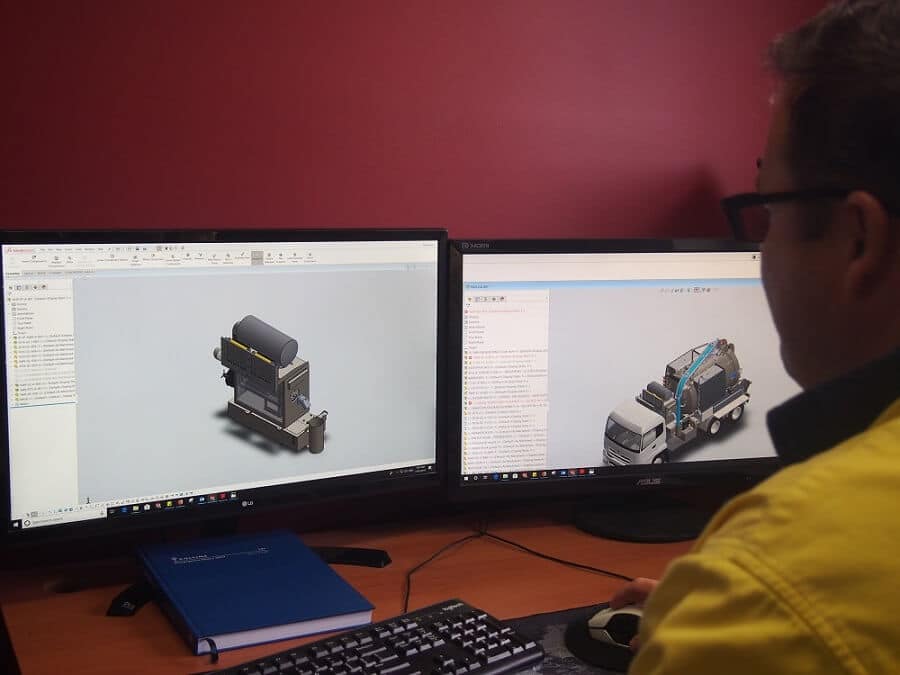

Design

With a team of qualified and local draftsmen, we design purpose built equipment to perform in any environment; under pressure, on your toughest jobs, and when you need it most.

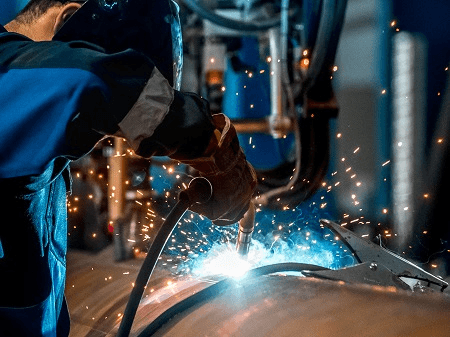

Manufacture

Certainly, there’s only one way to ensure consistent adherence to Australian standards, and that’s to keep manufacturing right here at home.

Service

We have a dedicated local servicing and parts division, in order to ensure our customers enjoy top performance now and in the future to come.